Search This Supplers Products:Metal Stamping Parts, CNC Machining Parts, RivetsSpringsWashersLathe Turning PartsElectrical Silver ContactsWood Parts

What is CNC Machining?What Can CNC Do for US?

time2023/05/16

- CNC machining is playing an increasingly important role in our daily life, which can help us achieve a better and safer life

This article will include the information not only about the Overview of CNC and its Feature and Machining Type,but also will mention about the common Material that can be CNC machined and the Field and performance about the CNC!

Overview

CNC is the acronym of computer numerical control,which means processing the material to produce a customized shaped parts by the tool of CNC machine controlled by the computer instead of manual work.

The CNC machining process typically begins with CAD, which can be used to describe specifications for a component, part, or other manufactured product. This design is then turned into a series of numerical instructions that a CNC machine may use to move and operate a variety of tools. A part may be completed in one CNC machine,but if the product is complicated,it may be moved manually or through robotic to several workstations to be shaped by different tools.

Feature

As one of subtractive manufacturing process,CNC machining has great difference with 3D printing and liquid injection molding which are known as additive and formative manufacturing processes.CNC machining services cut the material according to the custom’s requirement,while additive processes assemble material to produce the desired form and formative processes deform and displace stock material into the desired shape.CNC machining service has a various advantage,for example:

-Automaticity&High efficiency:All processing can be done by CNC machine. It is the basically unmanned factory if combined with automatic loading and unloading. CNC machining reduces the number of the operator, improves the working conditions, eliminates the marking, multiple clamping positioning, detection and other procedures and auxiliary operations, effectively improve the production efficiency.

--Adaptable:High adaptability to CNC machining objects. When changing the processing object,worker just need to reprogram and changing the tool, without other complex adjustment, this can help to shorten the production preparation cycle.

--High Precision&Stable Quality:The accuracy can be controlled within 0.005-0.01mm no matter how complex the products are.The size of the batch parts can be controlled well because of automatic therefore improve the precision.

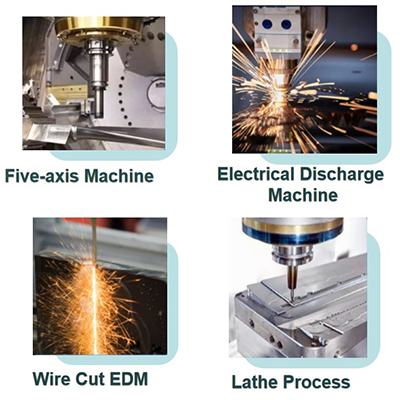

Machining Type

According to the difference mode of the machining,CNC machining can be typically divided into turning,milling mode.

Turning is a machining process which puts the material on the tool that keep material rotating while the cutting tools standstill.Because of that form of machining,the final products usually are circular cylinder.

TYPICAL TURNING PART

When it comes down to a CNC milling, with its rotating cutting tools, works better for more complex parts because the material keep standstill while the cutting tool move flexibly to shape the product.Milling parts can be any kind of configuration.

TYPACAL MILLING PART

For more complicated form,we can combine turning and milling process which is called machining centre.

Material

A wide variety of metal materials are available for CNC machining ,such as aluminum,stainless steel,brass,copper,steel, iron, alloy, zinc etc.

Application

You may wonder that what kinds of products need to be machined by the CNC,actually any metal parts that need tighter tolerance than other industrial,including automotive,airplane,aviation,navigation,agriculture and so on.

--Interested in CNC Machining Services? Try out LML's Instant Quoting Engine to make your project come to life. Free sample available.